The reason to work in this direction is the problems faced by the majority of farms equipped with modern agricultural machinery. One of such problems is the lack of knowledge of machine operators who drive these expensive smart machines. Not all machine operators are trained to work with on-board computers equally well, but the final economic result directly depends on how well these specialists perform the work. Besides, there is another technical problem: navigation lines for the machinery to drive according to the automatic driving system. Over several seasons, a large number of navigation lines, that are difficult to identify, have been collecting in the memory of on-board computers. Another part of the data is stored on flash drives, and the third one is in cloud services. All this can lead to confusion, the risk of data loss and, as a result, to irregularities in the technological procedure. In order for machine operators to be able to set up the display correctly, some companies constantly train them. Others create a special technical support service, which controls the setting up of smart machinery.

In the current situation of the coronavirus, it is impossible to gather a lot of people for training - this is a threat to their health. It is also too late to develop a separate technical service, if it has not been created yet though. The sowing process is on, and the machinery is already in the fields. Therefore, the key question is not “who is to blame?”, but “what to do”? The AG-DATA INTEGRATOR solution, already tested with John Deere machinery, is the way out.

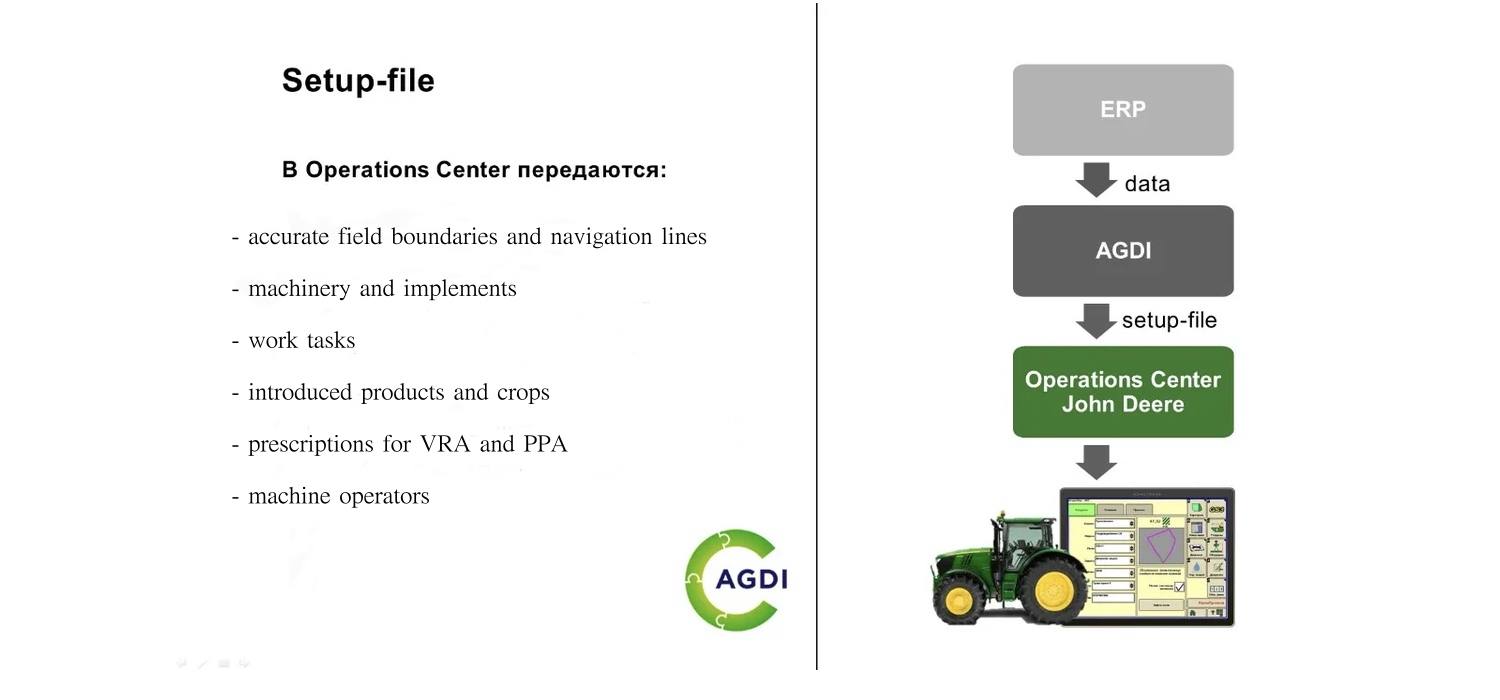

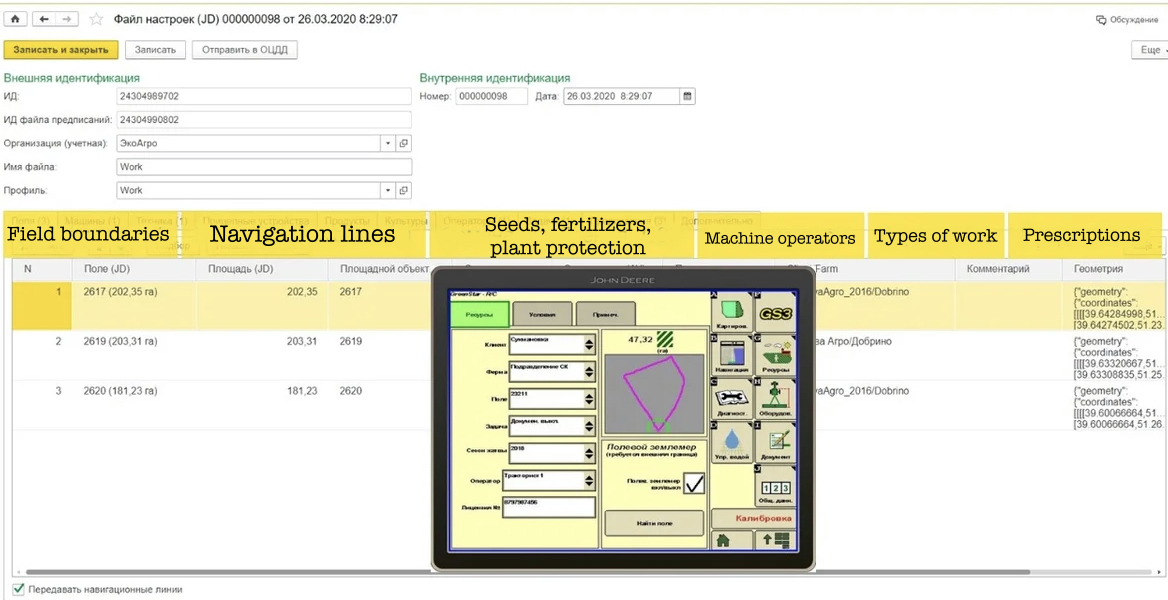

- Sending the machinery setup file to perform agricultural operations takes place through wireless data transmission through a special file of equipment display settings.

- Accurate field boundaries and guidance lines are transmitted to the machinery as well.

- The machine display setup file also contains information about implements, crops, application products, operators, tasks and prescriptions.

- The setup file, sent from the office, arrives on the machinery displays in a few seconds.

- The data on the display corresponds to the task sent from AG-DATA INTEGRATOR.

An additional advantage - tasks are created on the basis of uniform directories in the office system. This ensures the correctness of the subsequent work performed in the office. AG-DATA INTEGRATOR helps machine operators and transfer some of their work to dispatch services, thereby increasing the overall manageability of agricultural work. All that the machine operator requires to do is to receive the task and start work.

Easy, right?