Digital technologies for crops safety control. One more project that deals with the control over harvesting, movement and storage of grains and crops has been successfully implemented by CenterProgramSystem Company. The main idea of the project, that has been implemented in a large agro-industrial holding of the Russian Volga Federal District, was to use the customer's existing software and hardware systems, production and agronomic accounting systems and create an integrated module.

The central data warehouse is "CPS: Agroupravlenie" based on "1C: Enterprise" collects information about fields' production and their contours. It performs a plan-fact analysis of the field work progress, records data about the amount of harvest delivered to elevators, field piles and sugar beet stations. If we look at grain harvesting process, the technology looks in the following way:

• the driver delivers the vehicle for loading to the harvester;

• when loading is completed, the controller sends relevant information to be recorded in an electronic carrier located in the vehicle and duplicated in the GLONASS monitoring system;

• upon arrival at the unloading point, the information is read from the electronic carrier, processed and transferred to the “CPS: Agro-Management System”, which forms documents confirming that the harvest has successfully arrived from the field.

• the driver delivers the vehicle for loading to the harvester;

• when loading is completed, the controller sends relevant information to be recorded in an electronic carrier located in the vehicle and duplicated in the GLONASS monitoring system;

• upon arrival at the unloading point, the information is read from the electronic carrier, processed and transferred to the “CPS: Agro-Management System”, which forms documents confirming that the harvest has successfully arrived from the field.

Implementation of such a project revealed that there is no "single universal system" suitable for each client because hardly every enterprise has their weighing stations equipped with digital terminals, not every vehicle is capable of transmitting information about grain threshing. Not everywhere in the fields there is Internet connection, sometimes the whole process is poorly arranged, and also agribusiness faces certain problems with staff. Therefore, one of the immeasurable results of our work is that the client company has a greater understanding of "what is happening on the ground."

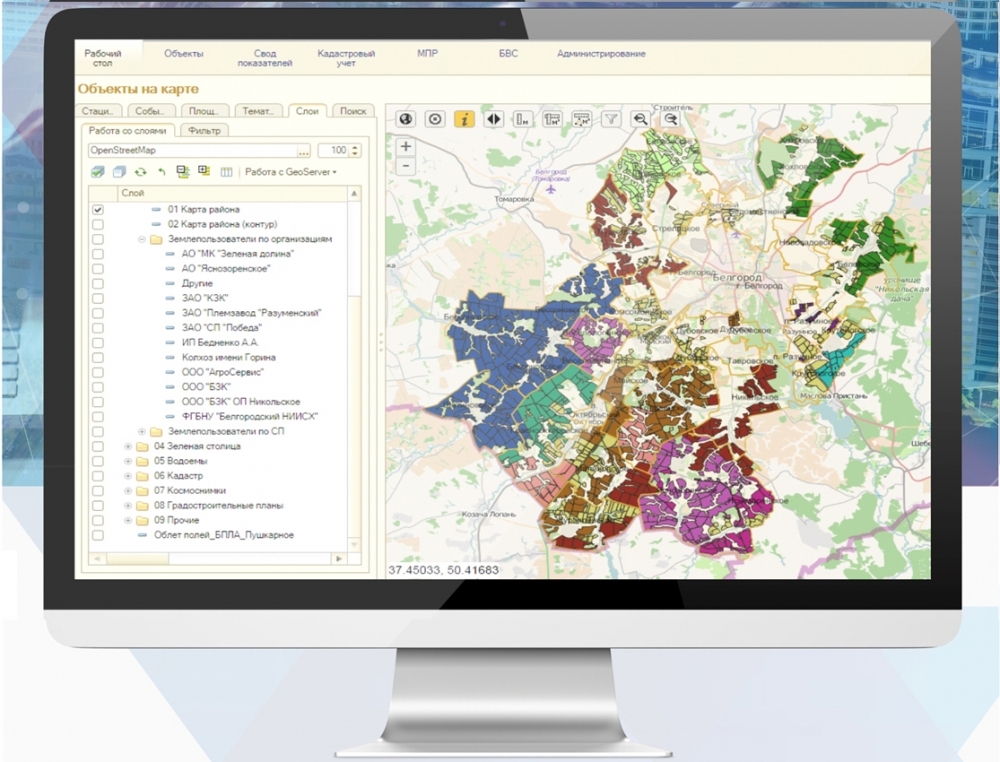

In 2023, we plan to expand the project in terms of automatization of the seeds, fertilizers and plant protection products’ write-off process which as we see it should be done right on the day when they leave the warehouse. The goal of the project is to increase the efficiency of cost accounting in the fields and checking the crop in the field, as well as to reflect the abovementioned information directly on the digital map of the fields. We have agreed with our customer-company that at the annual International Forum "Agromanagement 2023" our company will present the practical results of the grain and sugar beet harvesting project. The Forum will be held in Sochi (Krasnodar region) on October 11-12, 2023, registration of participants has started!

If you are interested in our tech solutions, please, do not hesitate to contact us any time.

If you are interested in our tech solutions, please, do not hesitate to contact us any time.